Proofing

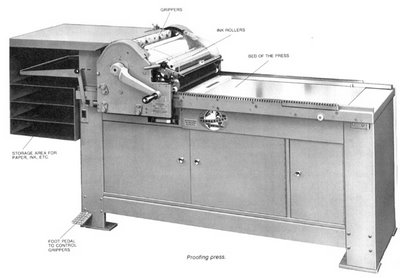

It should be noted that there is a difference between proofing type and actually printing it. A proofing press is a relatively small, slow-speed, hand-operated or power-operated press designed primarily for pulling a dozen or so proofs of each job. A printing press, on the other hand, is designed to operate auto matically at high speeds and print large quantities of a given job. The proofs pulled at the proofing press are called galley proofs or rough proofs. The reason for making these proofs is to allow both the typographer and the client to see that the job has been correctly set. Before the proof is sent to the client it is first proofread in the shop. Either the necessary corrections are made or it is indicated on the reader's proof that the errors have been noted and will be corrected. Several proofs, including the reader's proof, are then sent to the client for proofreading. These may be read by a proofreader, author, editor, or copy- writer, depending on the job. The designer also gets a proof so that he can make sure thejob has been set as specified. The corrections made on the various proofs are then transferred to a master proof. All corrections are marked eitherPE orAA. PE's are printer's errors and will be corrected free of charge by the typographer; AA's are the author's alterations and will be charged to the client. AA's include editor's or designer's changes.

The master proof is returned to the typographer, who makes all the corrections indicated. The corrected type is then locked up on the bed of the proofing press and a new proof called a reproduction proof, or repro, is pulled on a special coated paper. The quality of this proof is of the utmost importance, as it is used by the designer in the preparation of his mechanicals: it will be photo graphed and made into a printing plate for eventual reproduction.

After the job is completed, the type is cleaned cleaned and distributed; that is, put back into the type case. Great care is taken in distributing type, as letters carelessly thrown into the wrong compartments may not show up until a new job is set and proofed. Compositors are warned to "watch their p's and q's," as it is very easy to confuse certain letters, especially these. The leads, slugs, and furniture, arranged by thickness and length, are also put away for future jobs.

Despite the speed and skill of the compositor, handset type is a relatively slow, time-consuming process and is therefore too expensive for lengthy type Handsetting is recommended, however, for short "takes" (small amounts of copy) of either text or display type.

The master proof is returned to the typographer, who makes all the corrections indicated. The corrected type is then locked up on the bed of the proofing press and a new proof called a reproduction proof, or repro, is pulled on a special coated paper. The quality of this proof is of the utmost importance, as it is used by the designer in the preparation of his mechanicals: it will be photo graphed and made into a printing plate for eventual reproduction.

After the job is completed, the type is cleaned cleaned and distributed; that is, put back into the type case. Great care is taken in distributing type, as letters carelessly thrown into the wrong compartments may not show up until a new job is set and proofed. Compositors are warned to "watch their p's and q's," as it is very easy to confuse certain letters, especially these. The leads, slugs, and furniture, arranged by thickness and length, are also put away for future jobs.

Despite the speed and skill of the compositor, handset type is a relatively slow, time-consuming process and is therefore too expensive for lengthy type Handsetting is recommended, however, for short "takes" (small amounts of copy) of either text or display type.