The unit system is a measuring and counting system used by phototypesetting machines to determine when a line of type is readyto bejustified. It is based on the em of any point size of type being divided into equal, machine-recognizable increments called units.

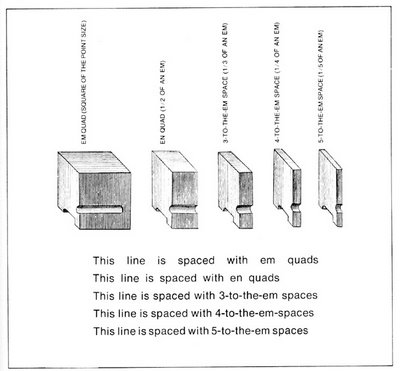

What Is a Unit? A unit is a subdivision of the em (the square of the type size). The number of units to the em varies from one manufacturer to another, although the most common number is 18. (We shall use an 18-unit system for our discussion.) Also, the size of the unit, like the size of the em, varies from one type size to another. For example, a unit of 72pointtype will be larger than a unit of 36point type. A simple method to determine the size of a unit is to think of it as 1 /18 of the type size.

Measuring Type in Units. The set width of the individual characters and spaces must be measurable in units. Therefore, each character is designed with a fixed unit width or unit value. This unit value also includes a small amount of space on either side of the characters to prevent them from touching when set.

To get an idea how this system works let's set the word Mat on an 18-unit system. The cap M is 18 units wide, the lowercase a 10 units wide, and the lowercase t 6 units wide. So the entire word is 34 units wide, regardless of the type size. By thus totaling the unit values of the characters and the spaces between the words, a counting mechanism (which can be part of the keyboard, computer, or phototypesetter) is able to measure a line of type in units and determine when it is ready to be justified.

Advantages of the Unit System. One advantage of using the unit system is that the .color" of the setting can be controlled by adjusting the units of space between the letters. This means that the type can be set with regular, loose, or VA, etc.

tight letters pacing. Letterspacing can also be adjusted on a selective basis, reducing space between certain letters while the rest of the setting remains the same. This is called kerning and is usually used in letter combinations that are improved by the deletion of one or two units of space, such as Te, Ta, Ve, AW,

Although the most common, the 18 is not an industry standard. The number of units to the em varies with the manufacturer and may be 4, 9, 12, 18, 32, 36, 48, or 64. The more units to the em, the closer together the letters can fit (let he more flexibility there is in wordspacing and letterspacing. However, although a greater number of units to the em results in a greater possibility of typographic refinement, for the averagejob there is a point beyond which further refinement is neither necessary nor noticeable.